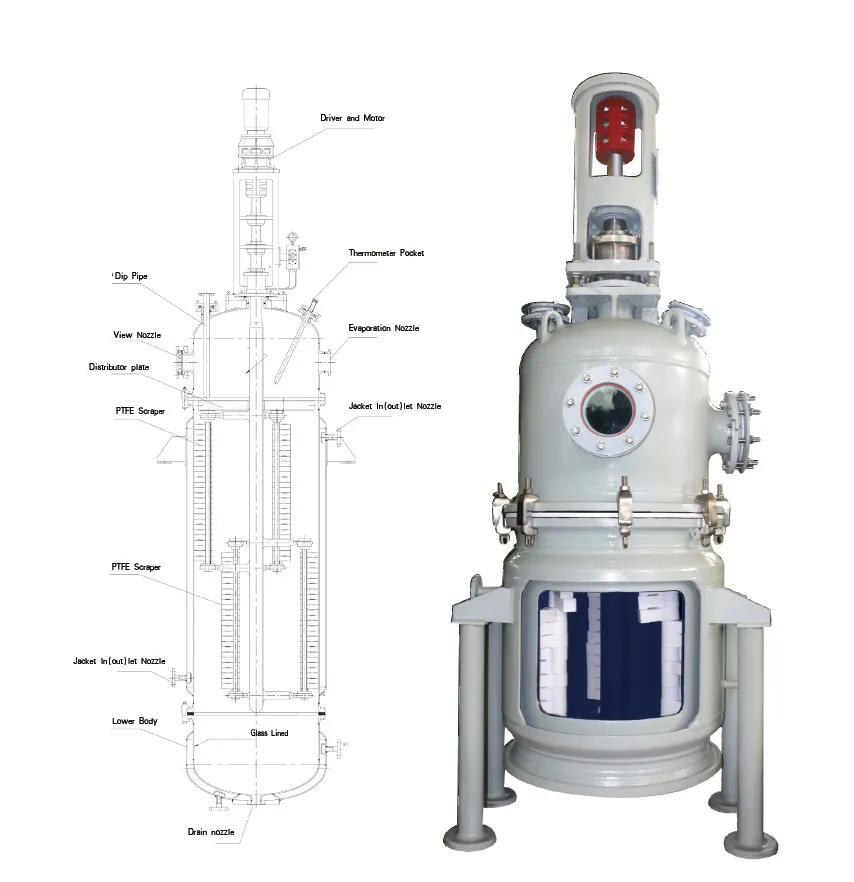

Glass-Lined Wiped Film Evaporator

Glass-Lined Wiped Film Evaporator

The glass-lined wiped film evaporator is a new type of high-efficiency thin film evaporation equipment. It has the characteristics of corrosion resistance, high vacuum, low boiling point and high yield, which is widely used in the processing of heat sensitive materials such as chemical, pharmaceutical, pesticide, waste water and waste acid treatment.

Designed for use with highly corrosive, viscous, or heat-sensitive compounds, Our glass-lined wiped film evaporator is crafted for excellence, featuring non-metallic materials like glass lining and PTFE in all contact areas. Ideal for handling corrosive media, high-viscosity substances, heat-sensitive materials, and high-boiling point liquids, this evaporator ensures superior performance and durability in demanding applications.

| Specification | Evaporation Area (㎡) | Inside Diameter of Evaporation Vessel (mm) | Length of Evaporation Vessel (mm) | Nominal Diameter of Evaporation Nozzle (mm) | Rotation Speed for Reference (r/min) | Motor Power (kw) | Total Height for Reference (mm) |

| 1 | 600 | 780 | 150 | 125 | 2.2 | -3450 | |

| 2 | 600 | 1350 | 150 | 125 | 2.2 | -4020 | |

| 3 | 600 | 1850 | 150 | 95 | 4 | -4600 | |

| 4 | 800 | 1830 | 150 | 95 | 4 | -4700 | |

| 5 | 900 | 2010 | 150 | 95 | 5.5 | -5040 | |

| 6 | 900 | 2370 | 150 | 95 | 5.5 | -5400 | |

| 7 | 1000 | 2460 | 150 | 95 | 7.5 | -5520 | |

| 8 | 1000 | 2750 | 150 | 95 | 7.5 | -5810 | |

| 9 | 1200 | 2600 | 200 | 85 | 11 | -6000 | |

| 10 | 1200 | 2900 | 200 | 85 | 11 | -6300 |

- Design pressure in the evaporation vessel: -0.1/0.25Mpa

- Design temperature in the evaporation vessel: 200℃

- Design pressure in the jacket: 0.6Mpa

- Design temperature in the jacket: 200℃

- High Heat Transfer Coefficient and Evaporation Intensity: Stable total heat transfer coefficient results from a major reduction in thermal resistance brought about by turbulent flow within the evaporator. Reducing the boiling point of the substance increases the temperature difference between the material and heating medium, therefore improving heat transfer and evaporation rates.

- Low-Temperature Evaporation: For heat-sensitive compounds, the capacity to sustain a high vacuum level enables much reduced boiling temperatures of the treated materials.

- Short residence time of the material within the evaporator guarantees product quality by preventing heat breakdown, polymerization, and deterioration.

- Versatility and Easy Operation: Suitable for handling practically all chemical media (excluding hydrofluoric acid, phosgene, concentrated phosphorous acid above 30% and 150°C, and strong alkalis with pH > 12 and temperature > 100°C), excluding fluoride ions, and provides simple maintenance, steady running conditions, and flexible operation.

Glass-lined thin-film evaporators are rather common in several sectors, including:

- Chemical: Handling strongly viscous and caustic materials

- Pharmaceutical: Managing high-purity, heat-sensitive materials

- Food and beverages: focusing and cleansing food products