Taiji, manufacturing and selling tens of thousands of sets of glass-lined equipment each year, has the largest amount of glass-lined equipment produced in the world, while almost getting no complaints from users due to quality problems. Moreover, the repair rate of all our equipment is much lower than that of the other manufacturers in this industry. However, our domestic counterparts are often complained for quality problems. That seriously affects the user's production. Even the most advanced manufacturers in the world can not get rid of quality problems. This is why most of customers choose Taiji and speak highly of our products.

Indeed, why Taiji glass-lined equipment is free from quality problems to enjoy demand over supply can be explained by following reasons.

Taiji's management is consistently earnest, rigorous and meticulous, which is well-known and recognized in this industry. Most importantly, Taiji is never making a false reputation, completely considerate for the sake of users, and persistently focusing on better glass-lined equipment. That guarantees more durable equipment for users and makes them more satisfied with Taiji's products and service.

Taiji attaches great importance to employees' benefits. We have invested 12 million RMB to build the Five-star dorms accommodating over 400 persons, and we provide the main management and technical backbones with houses, cars and other benefits. All the benefits and welfares help strengthen the bonds between the employees and the company, allowing for higher quality products and outstanding customer service.

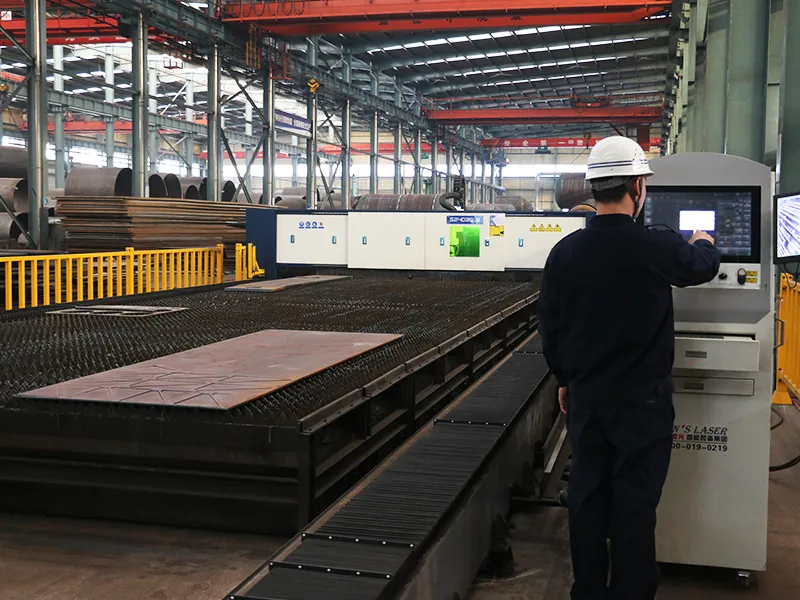

All the steel plates used in Taiji are supplied by leading steel plants in China, and are processed in strict accordance with the national standards. On the basis of foreign enamel technology, Taiji innovated and developed our own enamel to make the enamel and steel plates more closely combined after sintering. The physical and chemical performance of our enamel is much better than that of our competitors. For example, it boasts excellent resistance to acid and alkali corrosion, wear and thermal shock with variant temperature.

Taiji glass lining is made using cold spray technology and the enamel needs to be sintered on to the vessel internal wall layer upon layer. 6 times of cold spraying and sintering will be repeated. The potential defects (air bubbles, etc.) will have to be checked and removed after each sintering. Only after doing that can we conduct next cold spraying. Finally glass lining thickness reaches the required level and is inspected by a 20KV spark testing for the finished products.

But now most of the domestic manufacturers apply thermal spray and low temperature firing technology, with only once or twice enamel spraying and burning processes. Though this way could save cost greatly, it inevitably affect the products quality. What's worse, some potential defects such as air bubbles, iron burr, etc. have negative influence on the equipment.

Taiji has 36 proprietary technologies which make sintering technology more scientific. All the equipment including glass-lined steel reactor, glass-lined tank, etc. are manufactured completely in accordance with the national standards. Manufacturing all the equipment and spare parts in our own workshops greatly improve products stability.