As China's leading manufacturer of glass-lined equipment, Zibo Taiji Industrial Enamel Co., Ltd. has earned a global reputation for excellence. Our commitment to superior quality and unparalleled customer service has made Taiji a trusted choice for industries worldwide. Our products are distributed throughout China and exported to over 50 countries, serving a diverse range of applications.

The following eight advantages of Taiji Company are the reason for the high level of customer satisfaction with our products since the company's inception.

We boast an elite design team of 18 experts, divided into two departments serving both domestic and international clients. With their deep expertise and extensive experience, they deliver tailored solutions that precisely meet your material and production needs, ensuring both exceptional quality and outstanding value.

Our experienced and knowledgeable innovation team has developed high-performance glass-lined enamels such as TJ09, TJ2016, and TJ2021S, offering excellent resistance to acids, alkalis, high temperatures, wear, thermal shock, and mechanical impact, meeting international standards. Our R&D efforts in new products like large glass-lined equipment, sampling devices, removable mixers, silicon carbide heat exchangers, and thin-film evaporators have driven the healthy development of China's glass-lined equipment industry.

Our manufacturing team ensures reliability through expertise. Every process—cutting, rolling, welding, assembly, polishing, powder coating, firing, and final assembly—is meticulously executed. Defective products are rigorously excluded from subsequent stages, fundamentally guaranteeing the quality and integrity of our glass-lined equipment.

We feature cutting-edge equipment including laser cutters for precise material cutting, multiple 60-ton overhead cranes for handling large equipment, and robotic systems for precise drilling, alignment, and welding. Our advanced constant-temperature slow-burning furnaces ensure a tight bond between steel substrates and glass-lined coatings, significantly improving product durability and quality. We can produce glass-lined equipment up to 180,000 liters in capacity.

Our quality control team rigorously monitors every stage of production, adhering to strict standards. Defective products are not allowed to proceed to the next stage, ensuring that every piece of equipment meets the highest quality standards. This meticulous approach guarantees that our clients receive reliable and high-quality products.

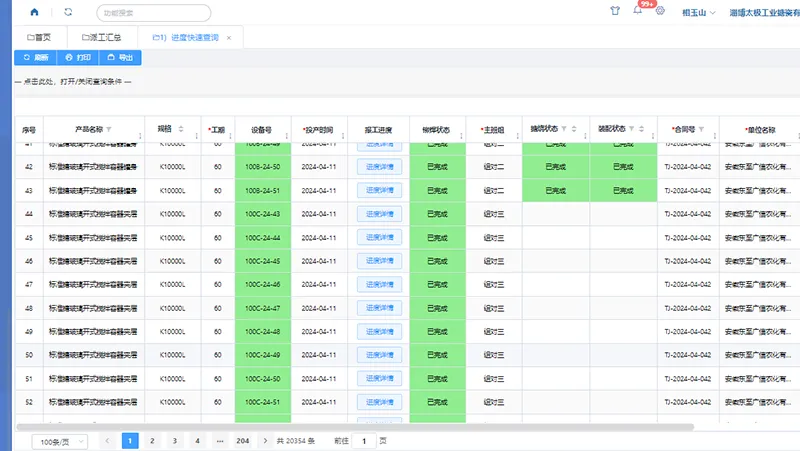

Taiji utilizes a comprehensive intelligent management system that integrates warehouse, sales, design, production, inspection, and shipping management. As one of the first companies in the industry to adopt such a system, we continuously upgrade it to ensure product traceability. The system tracks every process, component, and quality check, improving production efficiency and product quality.