High Performance Enamel

High Performance Enamel

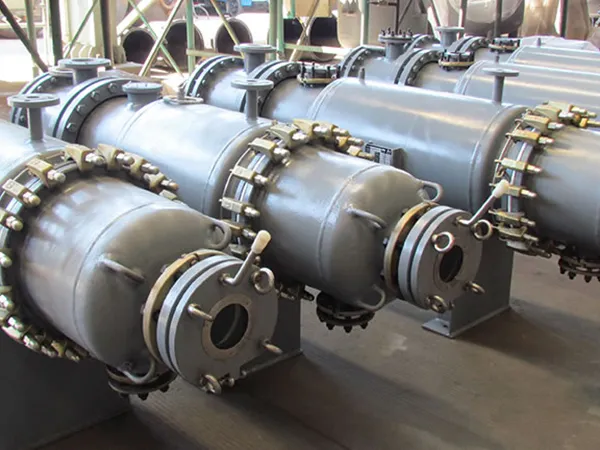

The TJ2009,TJ2016,TJ2021S enamel for glass lining is independently developed by Taiji, and it boasts a notably high performance that has reached an international advanced level. For example, the industrial porcelain enamel, also known as vitreous enamel comes with excellent resistance to corrosion of acidic and alkaline medium, mechanical shock and sharp temperature variation. Especially, it can resist the corrosion by all organic and inorganic acids, organic solvents and weak base except hydrofluoric acid and strong phosphoric acid.

TAIJI enamel adopts international advanced electric furnace sintering process and accurate compounding for enamel, strictly controls every production process and completely guarantees the quality of the enamel.

By means of state of the art electric furnace sintering process, with accurate compounding and rigorous process control, the quality of Taiji's enamel glass is totally guaranteed.

| Test Item | Standard Requirement | TJ-2009 | TJ-2016 | Test Method |

| Test Result | Test Result | |||

| Corrosion Resistance to 20% Boiling HCL for 168 h | ≤1.2g/m2d | 0.32 | 0.21 | GB/T 7989 |

| Corrosion Resistance to 0.1mol/L, 80℃ NaOH for 24 h | ≤5.0g/m2d | 1.95 | 1.42 | GB/T 7988 |

| Resistance to Sharp Temperature Variations | ≥200℃ | 205 | 210 | GB/T 7987 |

| Mechanical Impact Resistance | ≥220x10-3J | 268 | 278 | GB/T 7990 |

| Corrosion Resistance to Boiling Water for 336 h | ≤5.0g/m2d | 0.35 | 0.31 | GB/T 7989 |

| Average Coefficient of Thermal Expansion | / | 9.86/10-6k-1 | 9.75/10-6k-1 | GB/T 7991.7 |

The corrosion curve below illustrates the corrosive nature of typical acidic and alkaline media.

- Low Corrosion Rate (<0.1 mm/year): When the corrosion rate is less than 0.1 mm per year, it indicates that the medium is minimally corrosive to glass-lined surfaces. Such media are recommended for use with glass-lined equipment.

- Moderate Corrosion Rate (0.1-0.2 mm/year): A corrosion rate between 0.1 and 0.2 mm per year suggests that the medium exhibits moderate corrosiveness towards glass-lined surfaces. Regular inspections of the glass-lined layer are necessary in these conditions.

- Severe Corrosion Rate (>0.2 mm/year): Corrosion rates exceeding 0.2 mm per year indicate a high degree of corrosiveness that can significantly damage glass-lined surfaces. The use of glass-lined equipment is not recommended in such media.

The accompanying graph shows how different media at different temperatures and concentrations corrodes, highlighting their effect on the glass-lined porcelain layer.

We ensure a high-quality undertaking for our customers over the entire manufacturing process, from raw material machining up to installation.