Speed Reducer (for Glass-Lined Reactor)

This type of speed reducer is featured by high transmission efficiency, exceptional stability, low noise, compact structure, reliable operation and long service life etc. Our glass-lined reactor employs this transmission device and is fitted with different power models according to the equipment capacities.

Technical Parameter

| Power KW | Reducer | Speed | Reactor | ||

| i =11 | i =17 | i =23 | |||

| 0.75 | BLD-1 | 130 | 85 | 63 | 50L -100L |

| 1.1 | BLD-1 | 130 | 85 | 63 | 200L |

| 3 | BLD-2 | 130 | 85 | 63 | 300L -800L |

| 4 | BLD-3 | 130 | 85 | 63 | 1000L -2000L |

| 5.5 | BLD-3/4 | 130 | 85 | 63 | 2500L -5000L |

| 7.5 | BLD-4 | 130 | 85 | - | 3000L -6300L |

| 11 | BLD-4 | 130 | 85 | - | 8000L |

| 11 | BLD-5 | 130 | 85 | - | 10000L |

| 15 | BLD-5 | 130 | 85 | - | 12500L |

| 18.5 | BLD-6 | 130 | 85 | - | 15000L -20000L |

With optimized and modular design, the worm gear reducer features compact size, light weight, large transmission torque, smooth and stable start, fine gear ratio grading, etc. According to customers' requirements, it can be installed at the different positions on the glass lined reactor. Gear is made of superior high strength alloy steel with surface carburizing and hardening treatment, ensuring strong bearing capacity and notable durability.

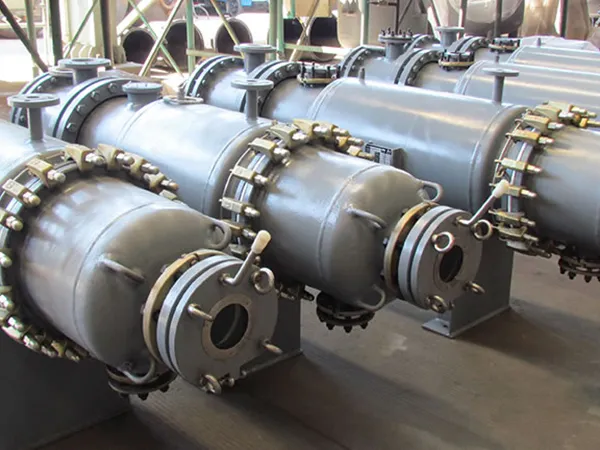

Boost Efficiency with Our High-Strength Four-Post Racks

Designed for hard use, these four-post racks offer exceptional durability and stability. Large bearing seats and fast-release design help to simplify maintenance and save downtime. Our racks improve general operational efficiency and safety by doing away with the need for cranes and unstable snap rings. This means on-site personnel may execute maintenance jobs promptly, considerably enhancing operating efficiency.

Safety is our top priority. Our four-post racks provide a safe and steady support structure, therefore removing the possibility of agitator mishaps and vessel damage. The shape of the quick-release also makes it less likely that someone will make a mistake while maintaining it. Plus, there's no need for height modifications or extended connections, which means decreased procurement costs and improved versatility for your equipment.

We ensure a high-quality undertaking for our customers over the entire manufacturing process, from raw material machining up to installation.