Glass-Lined Flush Valve

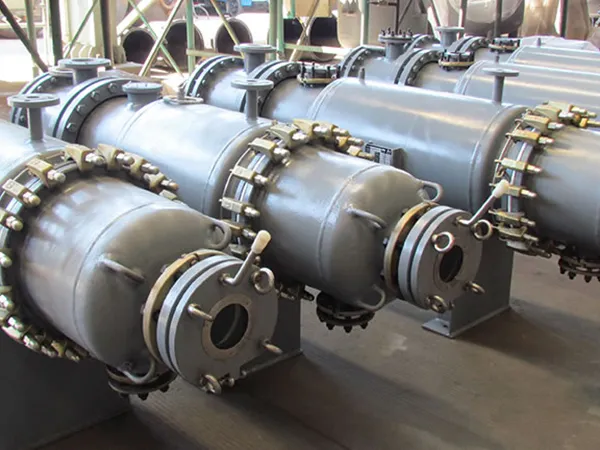

The glass-lined flush valve is specially used as the flush bottom valve or bottom outlet valve for glass-lined reactors. The valve body is fabricated from cast iron or steel, and both the inner surface of valve body and outer surface of valve core are lined with our high performance glass. The valve core is sealed by compressing the PTFE seal ring. This glass-lined discharge valve is categorized into two types: Upper-Moving Type and Lower-Moving Type.

| Nominal Pressure (MPa) | PN0.4 PN0.6 | PN1.0 | ||||||||

| Nominal Diameter (mm) | 65/32 | 80/50 | 100/50 | 125/80 | 150/100 | 65/50 | 80/50 | 100/65 | 125/100 | 150/100 |

The flush valve can be fitted with tantalum tip to realize real time measurement of temperature in the reactor and thereby avoid temperature delay or error caused by using thermowell. In addition, by changing the air actuated device for valve core, you can remotely control the discharging of reactor.

This flush valve with bellows seal is an alternative to the flush valve with packing seal. It ensures reliable sealing performance, ease of cleaning and capability to withdraw higher operating pressure. The valve body is molded using stamping method which drastically improves the material strength. Operating temperature: -19℃-200℃; working pressure: 0.6Mpa-1.6Mpa.

| Nominal Pressure (MPa) | PN1.0 | PN1.6 | ||||

| Nominal Diameter (mm) | 100/80 | 125/80 | 150/100 | 100/80 | 125/80 | 150/100 |

We ensure a high-quality undertaking for our customers over the entire manufacturing process, from raw material machining up to installation.