Glass-Lined Nutsche Filter

Glass-Lined Nutsche Filter

Features

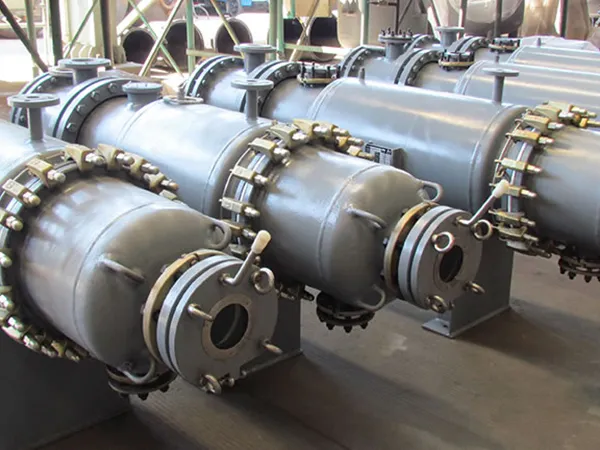

- The glass-lined filter manufactured by Taiji is widely used for solid-liquid separation of corrosive materials. Especially, it is ideal for the solid-liquid separation of poisonous medium, flammable and explosive medium and the medium that should be avoided contacting with air.

- The nutsche filter can be used under fully vacuum environment or where the maximum positive pressure is 6kpa.

- The jacket that we design for the solid-liquid separation filter can heat or cool the liquid according to actual needs.

- We design a hydraulic lifting device at the bottom of this filtration equipment. It helps to remove filter cake and replace filter cloth.

A glass-lined nutsche filter is a specialized filtration equipment commonly used in the chemical and pharmaceutical industries.

Here's how it works:

- A layer of glass enamel is carefully fused onto a metal surface, creating a durable and beautiful finish. The process involves subjecting the metal to a high temperature of 950°C, ensuring a strong bond between the enamel and the surface.

- This creates a powerful connection, providing the filter with the chemical stability of glass and the durability of metal.

- The filter utilizes a porous medium to effectively capture solid particles from a mixture of liquid and solid, effectively separating the two components.

In addition, the Glass-Lined Nutsche Filter is highly regarded for its straightforward design, ability to withstand corrosion, and user-friendly operation.

This device is specifically designed to efficiently filter, wash, and dry solid and liquid materials in a fully enclosed process. For multifunctional capabilities this machine is highly popular in the chemical processing, fine chemicals, and pharmaceutical industries.